Produkt Verwendung

Dieses Produkt wird zur schnellen Abkühlung von gekochtem Reis verwendet. Vakuuman Kühlung sorgt für hohe Geschwindigkeit und keine Verunreinigung, wodurch das fertige Produkt sofort verpackt werden kann.

Anwendbare Kunden

Dieses Produkt ist für Unternehmen wie Vorverarbeitungsbetriebe und Zentralküchen geeignet, die gekochten Reis im Großmaßstab herstellen.

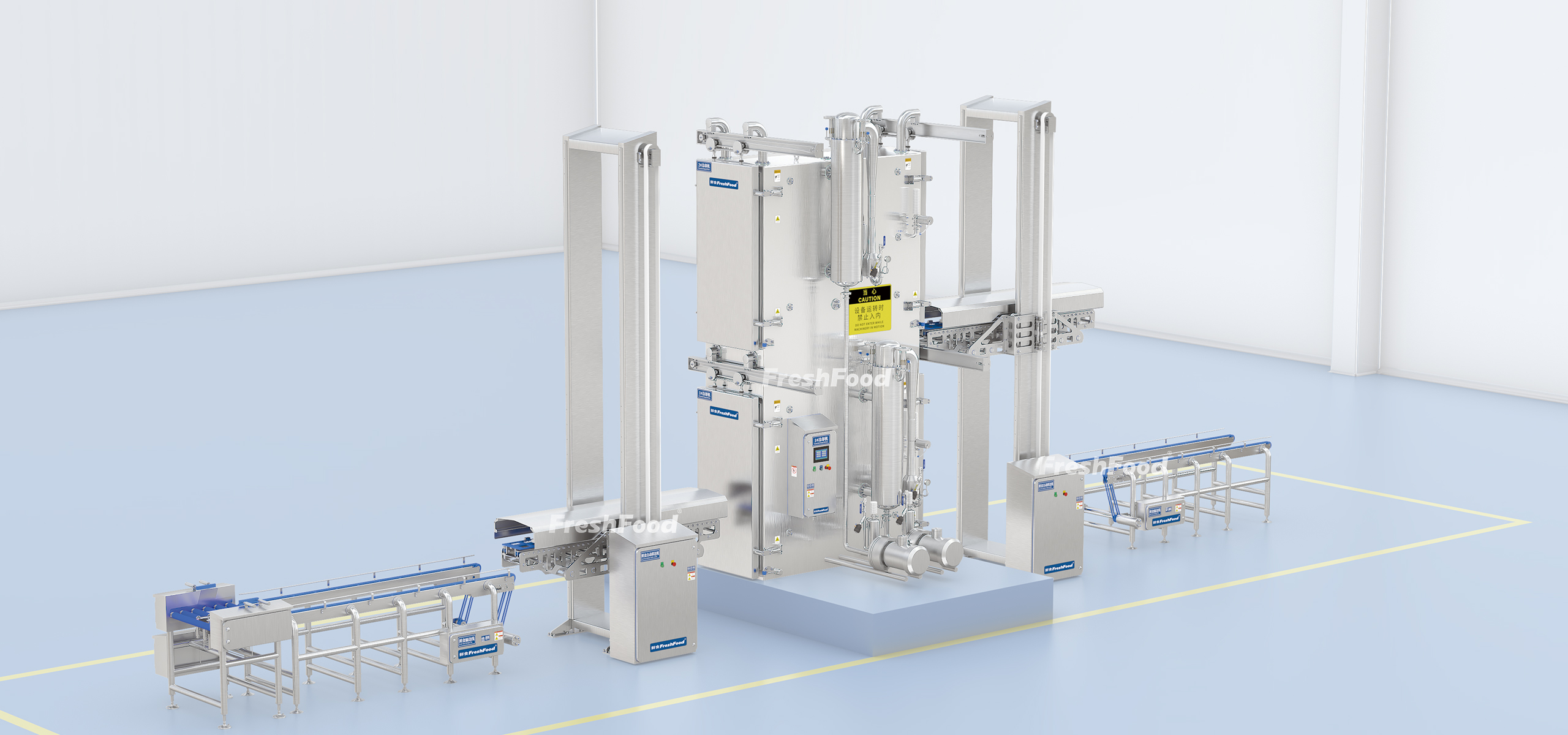

Ablauf des Betriebs

Automatische Fütterung

Vakuumkühlung

Entladung

Unsere Vorteile

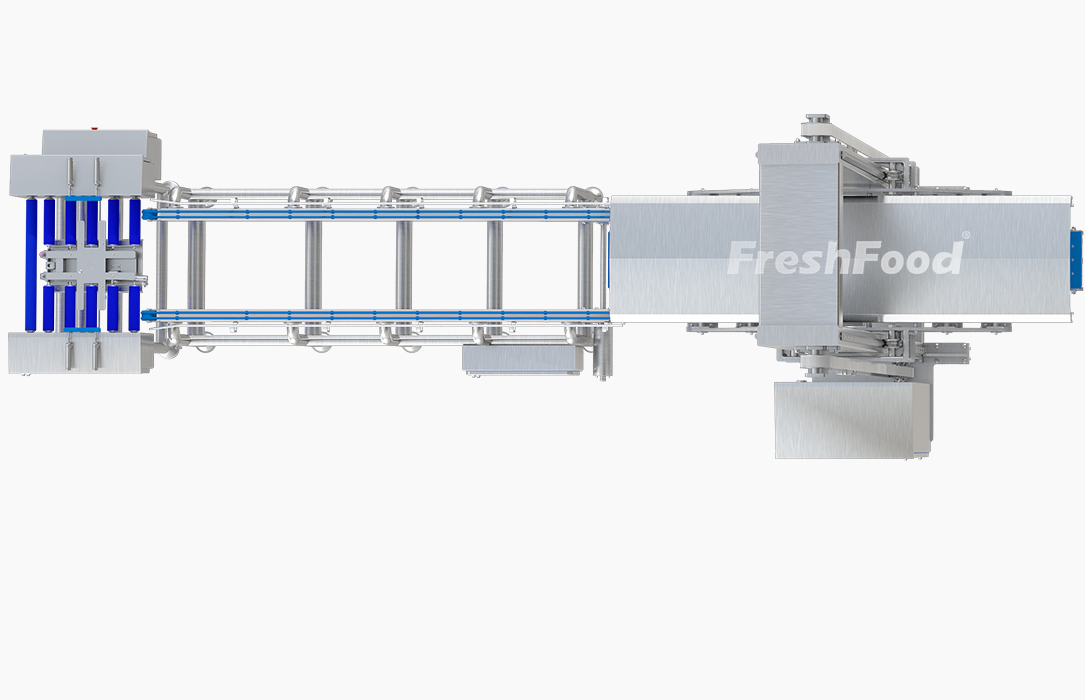

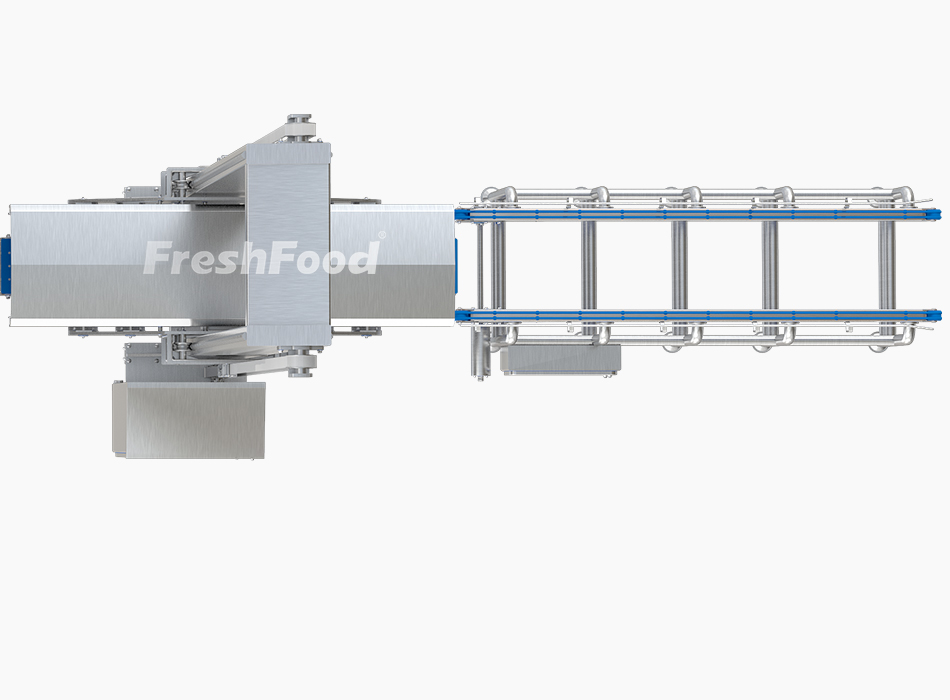

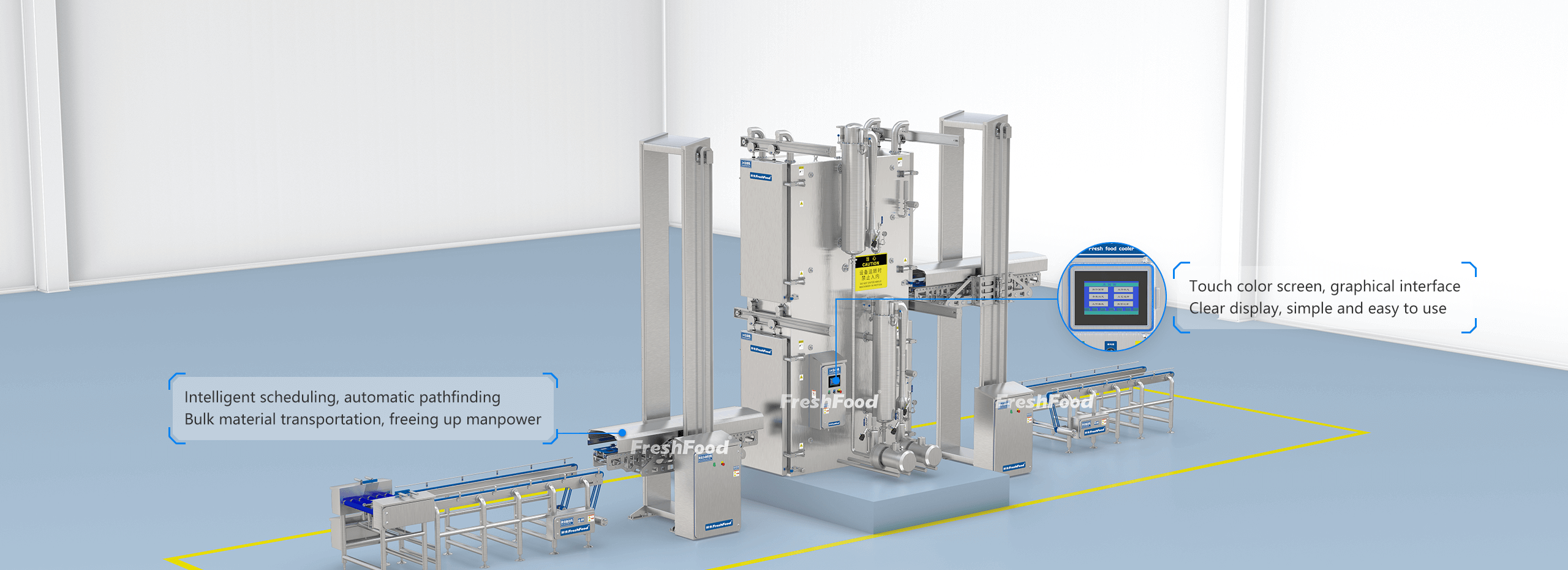

Die Produktionslinie arbeitet automatisch, und das System regelt die Wassertemperatur selbstständig ohne manuelle Operation. Benutzer können den Betriebszustand über eine Touch-Oberfläche in Echtzeit überwachen und existierende Prozessparameter schnell aufrufen.

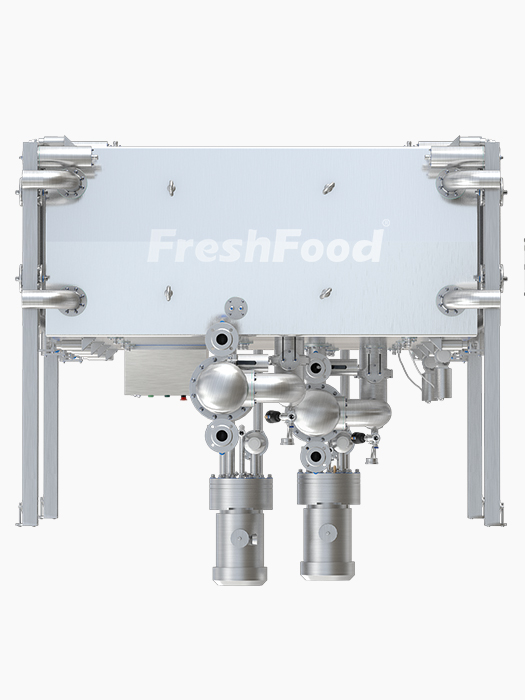

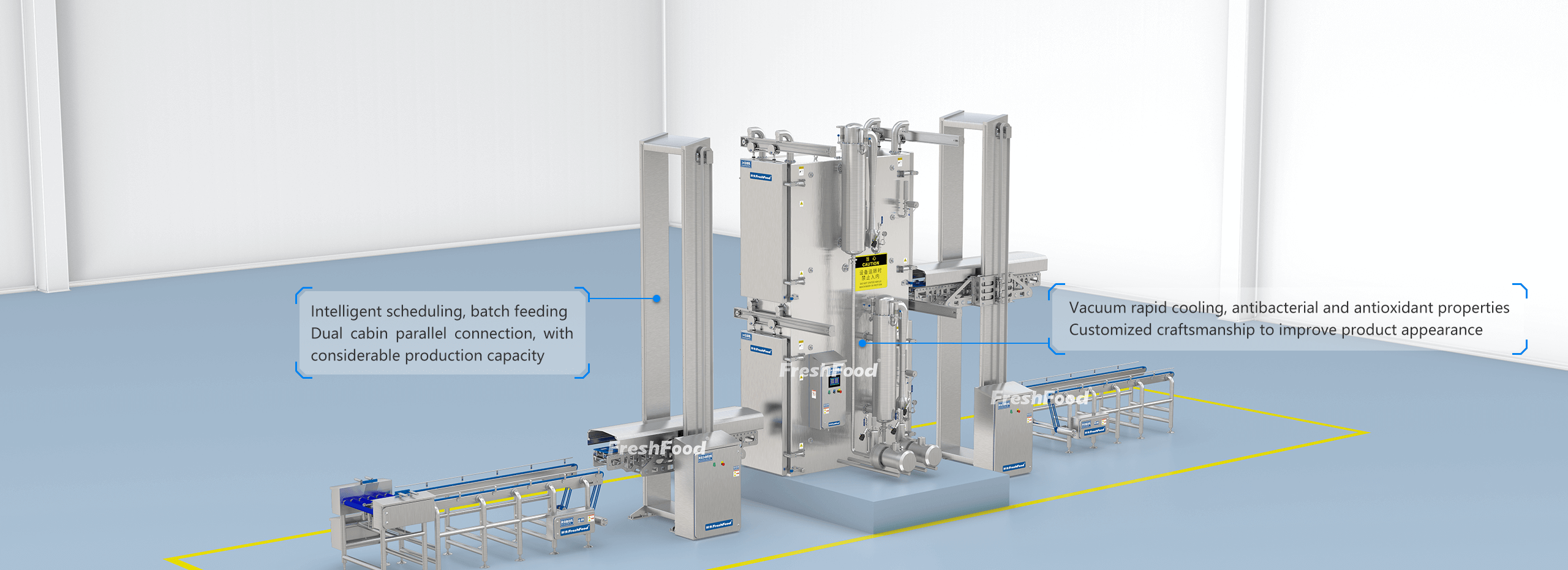

Es dauert nur 5 Minuten, um von 85°C auf 15°C abzukühlen; mit zwei Kammern, die vertikal parallel angeordnet sind, arbeitet das System effizient. Der gesamte Prozess ist frei von Verunreinigungen und hygienischer. Vakuuman Kühlung stellt sicher, dass die Reiskörner klar und glänzend sind, was die Qualitätskontrolle verbessert.

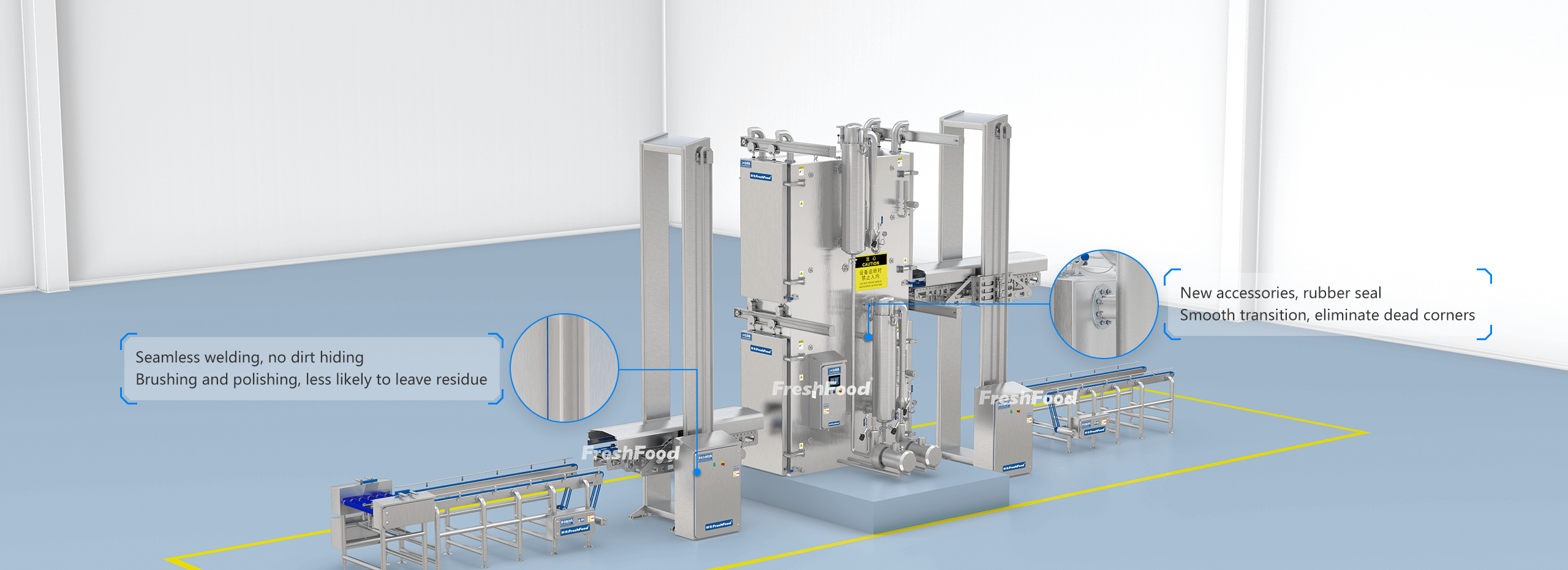

Durch die Anwendung neu entwickelter eigener Komponenten, Gummiverschlüsse, nahtloser Schweisung und eines leicht abbaubaren Designs dient das Gerät der täglichen Hochtemperatur- und Hochdruckreinigung, verhindert Schmutzrückstände und kontrolliert das Bakterienwachstum.

Prozessautomatisierung spart Personal kosten. Die Kühlmaschine hat ein doppeltes Kammerdesign, das vertikal übereinandergestapelt ist, um Platz zu sparen. Die Kühlkammer ist mit einer Isolierschicht ausgestattet, die Wärmedämmung und Energieeinsparungen ermöglicht.

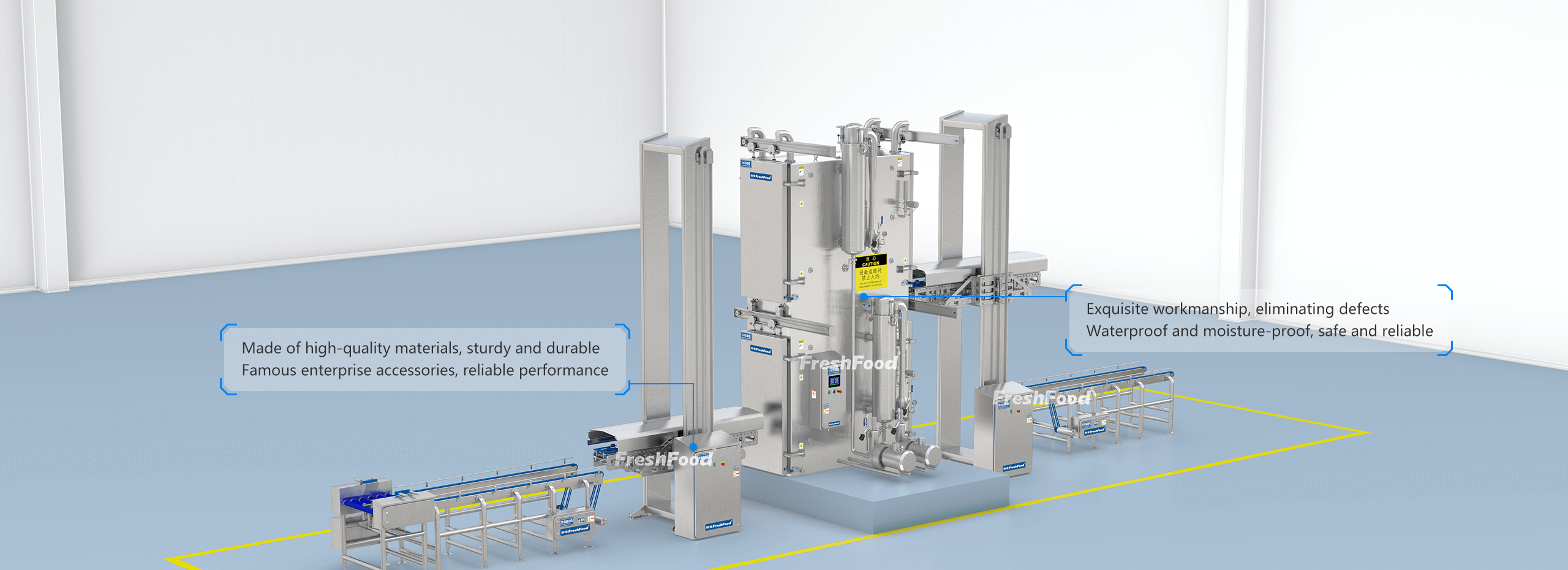

Hochwertige Rohstoffe, Komponenten internationaler Marken, wasserdichte und staubdichte Behandlung, präzise Fertigungsverfahren und strenge Qualitätskontrolle stellen sicher, dass das Produkt langlebig, sicher, zuverlässig und stabil performiert.

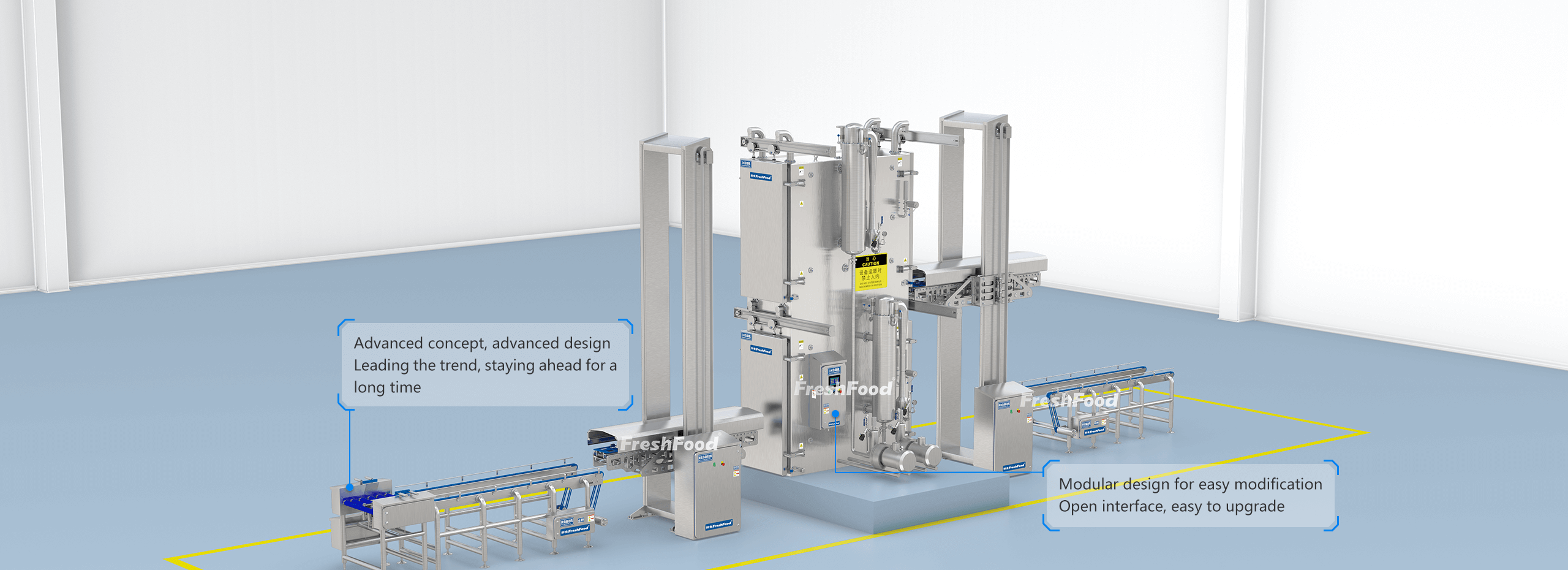

Durch die Integration fortschrittlicher Konzepte und Technologien wie IP69K, umweltfreundlich, Industrie-Internet der Dinge (IIoT) und intelligente Steuerung wird sichergestellt, dass die Ausrüstung ihre funktionale Vorausschau über den langen Zeitraum beibehält und zukünftige Entwicklungsanforderungen erfüllt.

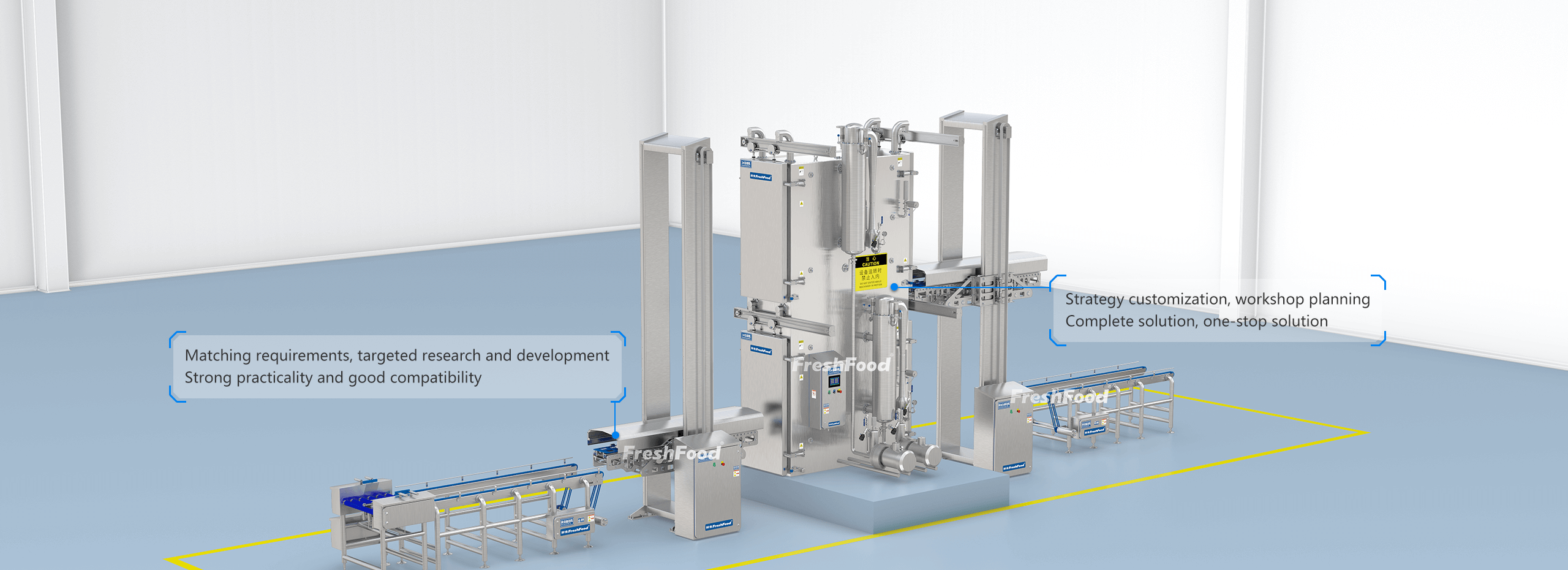

Wir können für Sie produktionstechnische Prozesse und Anlagenlayoutzeichnungen anpassen, die mit Ihrem Produkt kompatibel sind, und zusätzliches Automatisierungsgerät entlang der Prozesskette zur Verfügung stellen, um eine integrierte intelligente Frischproduktefabrik aufzubauen!